Cathodic protection is a common technique used to provide life extending protection from corrosion for steel tanks and pipelines.

There are two basic methods used to provide cathodic protection to steel tanks. By far the most common and simplest method of protection is a sacrificial anode system. Most states require a simple inspection of this system every three years by a qualified inspector.

An impressed current cathodic protection system is the second type. Typically, it requires a detailed inspection every three years and a bi-monthly inspection of the power supply (called a rectifier). In order to insure the system is operating within its design parameters, you should perform certain tests:

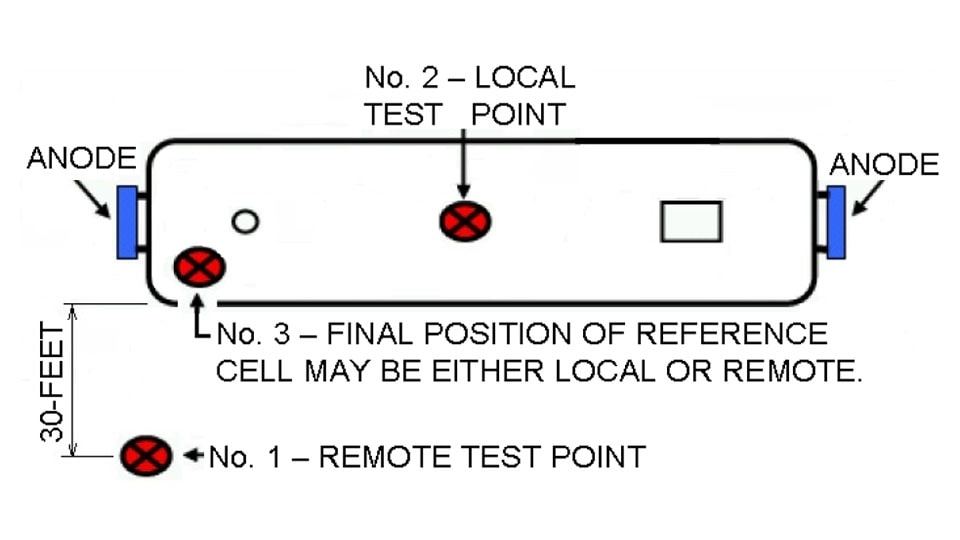

Reference electrode placement for sti-P3® tanks.

- The rectifier requires an uninterrupted supply of electricity, so always check to see that the circuit breaker that supplies electricity to the rectifier is ON.

- Inside the rectifier, there is another circuit breaker that allows electricity to operate the unit. Be sure that it is ON.

- Generally, there are two meters inside the rectifier, a voltmeter and an ammeter. Both volt and amp readings should be collected and recorded monthly:

- The volt meter indicates there is AC power being supplied to the rectifier. The value displayed on the volt meter indicates the amount of power being supplied to the anodes. The volts can be adjusted by trained personnel, if necessary.

- The amp meter indicates the amount of current (amps) that is flowing from the anodes to the underground tank. Amps will fluctuate depending on weather, climate, and changes in the level of protection, but cannot be adjusted. If the amp value on the meter changes more than 10% from the previous month, contact your corrosion control representative and follow their instructions.

Volts and Amps

Understanding the difference between the electrical measures of volts and amps is easy, and applies no matter where electrical power is used.

A volt is a unit of electricity that is a measure of the electromotive force that exists in the wire circuit. A simple comparison is to the pressure (psi) that exists in a pressured water pipeline.

Amps are the units that measure the current being pushed through the system, similar to the gallons per minute you receive as a result of water pressure.

Therefore, the greater the number of volts, the more amps are delivered. This is true of both alternating current (AC), which is used in your home, office, and to power street lights; and direct current (DC), which is used in batteries, battery chargers—and cathodic protection systems.

A properly installed cathodic protection system can prevent corrosion on steel tanks and pipelines, By performing routine testing and complying with federal, state, and local regulations, you can sustain the life of steel tanks indefinitely.

Testing Your Tank’s Cathodic Protection System

- Two (2) basic methods: sacrificial anode and impressed current.

- The most common, sacrificial anode system has an anode that operates exactly like one in a home hot water heater.

- Cathodic protection systems need a simple inspection at least every three (3) years.

- It’s easy to provide monthly inspections of impressed current cathodic protection systems (download monthly inspection checklist).

- Remote monitoring of cathodic protection systems by trained corrosion engineers is readily available.

Resource Type

- Recommended Practice

Topic

- Cathodic Protection Training

- Underground