This data has been prepared to assist the buyer and designer in the selection of a steel water storage tank appropriate to local needs.

The sizes and design data are examples of typical vessels.

Why Buy a Welded Steel Water Storage Tank?

Welded steel water storage tanks satisfy the four basic criteria of low cost, reliability, versatility and availability. Steel structures can be constructed in a variety of shapes, limited only by the imagination of the designer. The three primary categories of storage tank design are reservoirs, standpipes or elevated tanks. In addition, special tank designs are increasingly requested by end users.

When selecting a water storage tank to fill the needs of a city or industry, a comprehensive evaluation should be made of all the alternate designs available. Members of the Steel Tank Institute/Steel Plate Fabricators Association (STI/SPFA) give important factors, such as potential service and economic considerations, the careful attention they deserve.

It is the purchaser’s responsibility to select the size and type of tank to best meet a set of operating conditions. The rules of the American Water Works Association (AWWA) are then applied to the task of designing the appropriate tank. The purchaser will want to consider the following factors in detail.

Cost

Reliability

Versatility

Availablility

Design and Construction

Virtually all water storage vessels in the United States are designed and constructed in accordance with Standard D100 of the American Water Works Association. This is a public standard to be used, without reservation, by anyone involved in water storage.

A water storage tank usually is located in the midst of a heavily populated area, often on the highest elevation available. Public safety is the underlying concern of AWWA Standard D100, a safeguard that has existed since 1935. Anyone dealing regularly wth water storage tanks should obtain a copy of the complete standard.

AWWA D100 offers two different design bases, the standard (or basic) design and an alternate design as outlined in Section 14. The alternate basis permits higher design stresses in return for a more refined engineering design, more rigorous inspection, and the use of shell plate steels with improved toughness. Section 14 is applicable only for reservoirs and standpipes.

Engineering and Materials

How Steel is Supplied

The production of steel plate is a closely controlled procedure, from furnishing the raw material to shipment of the completed product. Steel is inspected at every point of manufacturing to assure uniformity of strength and thickness. This uniformity is very important to the design and engineering of a steel water storage tank. There is no guesswork as to tensile strength, ductility or flexiblility.

Ductility also gives steel the ability to withstand abnormal shocks such as earthquakes, tornadoes, and extreme temperature changes. In this respect, steel surpasses all other materials because it has maximum strength with maximum ductility. The minimum tensile strength of steel normally used for water storage vessels is 55,000 pounds per square inch.

Reliability is a necessity for any water storage vessel. Engineers can depend on steel to do the job for which it was designed, and its reliability includes the ability to withstand many unexpected or emergency conditions that would spell disaster for concrete tanks.

The provision for bottle-tight joints is another area in which steel excels. Joints in steel shell plates are completely watertight and will stay that way for the life of the vessel.

Building a steel water storage tank is a controlled process. All materials used in its construction are subjected to rigid examination. Its erection is carried out to an established standard by a proven technique. Its performance characteristics will be predictableon the day it is completed and after 10 years of service. This is the owner’s assurance that a steel tank will carry the workload as soon as the last plate is welded. And it will continue to do so, even under weathering and conditions of service and stress that would be cause for grave concern if the tank were constructed of any other material.

All steel plate is manufactured to American Society for Testing and Materials (ASTM) Standards, a national set of specifications. These standards are revised periodically to report new specifications and changes to existing ones. This ensures uniformity of product purchased anywhere in the country. Mill test reports are available for every piece of steel that is manufactured in the United States.

Loads to Be Considered

Other than the loading from the tank full of water, there are three loads that must be considered in the design of a tank-wind, snow and earthquake. Wind load generally is based on an assumed wind velocity of 100 MPH, although a higher velocity is used in some instances. Snow load is assumed to be 25 PSF of horizontal projected area. This loading generally is used even in areas where snow does not occur.

Because of their flexibility, steel tanks have an excellent safety record in earthquakes. Steel has the ability to absorb large amounts of energy without fracture. The purchaser should specify if provisions for earthquake resistance should be included in the design. The design percentage used, unless otherwise specified by a local code stipulated by the purchaser, shall be determined by the location of the tank with respect to the zones by the seismic risk map published in AWWA Standard D100.

Control of Fabrication and Welding

Just as the production of steel plate is under strict ASTM controls, shop fabrication is performed in accordance with the latest AWWA requirements. Likewise, field erection of a steel water storage tank is performed according to strict specifications regarding assembly, welding and inspection.

The erection contractor must have qualified welding procedures, and all welders and welder operators must pass qualification tests in accordance with Section IX of the ASME Code. Welded joints generally are inspected by the radiographic method, although the sectioning method also is used. These inspection procedures are detailed in Section II of AWWA Standard D100.

Certification of Protective Coatings

Guarantee

Types of Vessels

When additional storage capacity is needed in the water system, engineers must select the storage structure that best suits the circumstances. The quantity of storage required, the local topography, and system pressure must all be analyzed in making this selection.

New design and engineering concepts and materials make possible water storage facilities that combine utility with aesthetic considerations. Often they pennit a dual use of community land-for recreational and other purposes, as well as for waler storage.

The three basic types of steel water storage structures; reservoirs. standpipes and elevated tanks, are available in a variety of eye-appealing designs that can blend into your community’s landscape.

Reservoirs

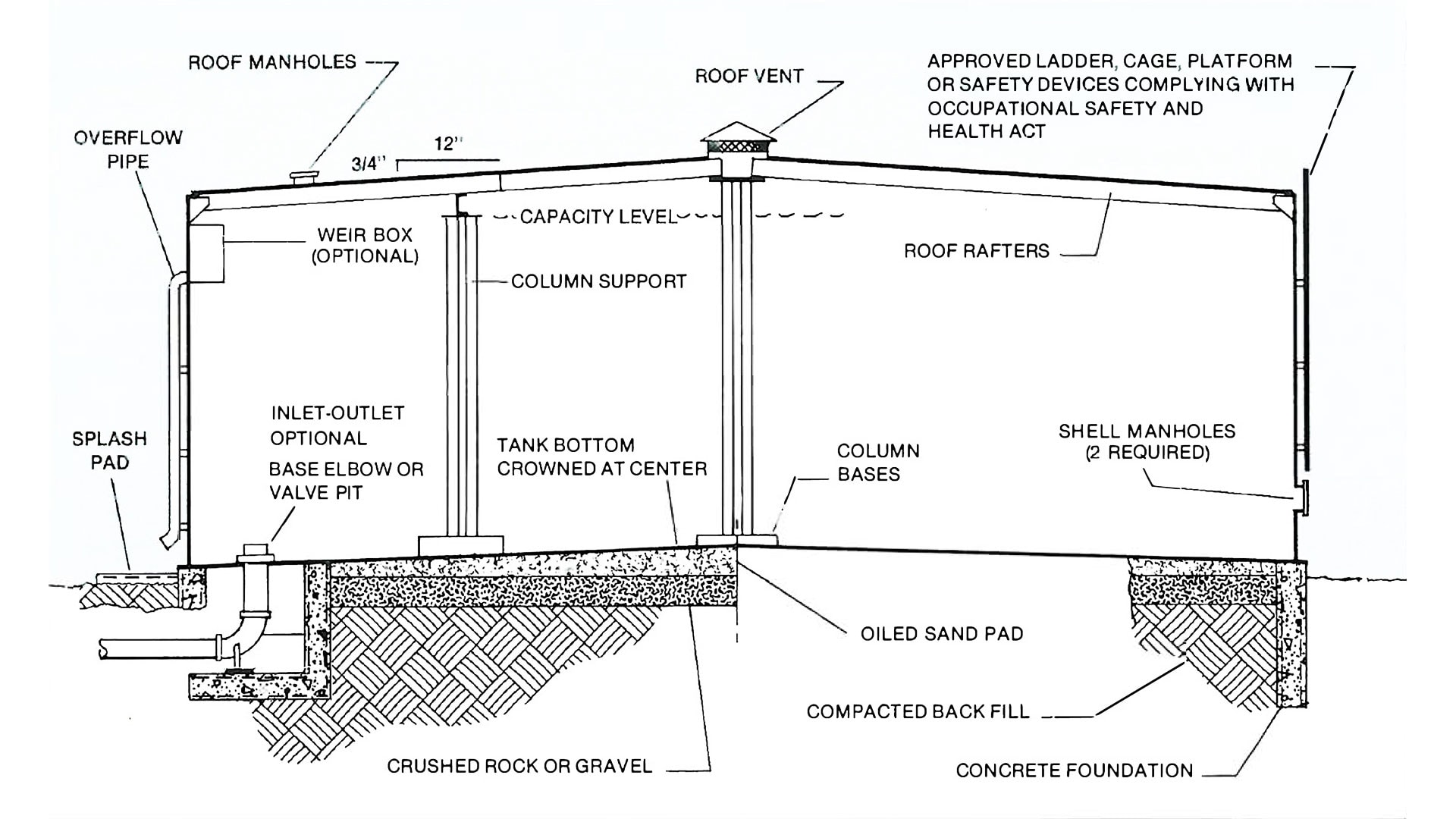

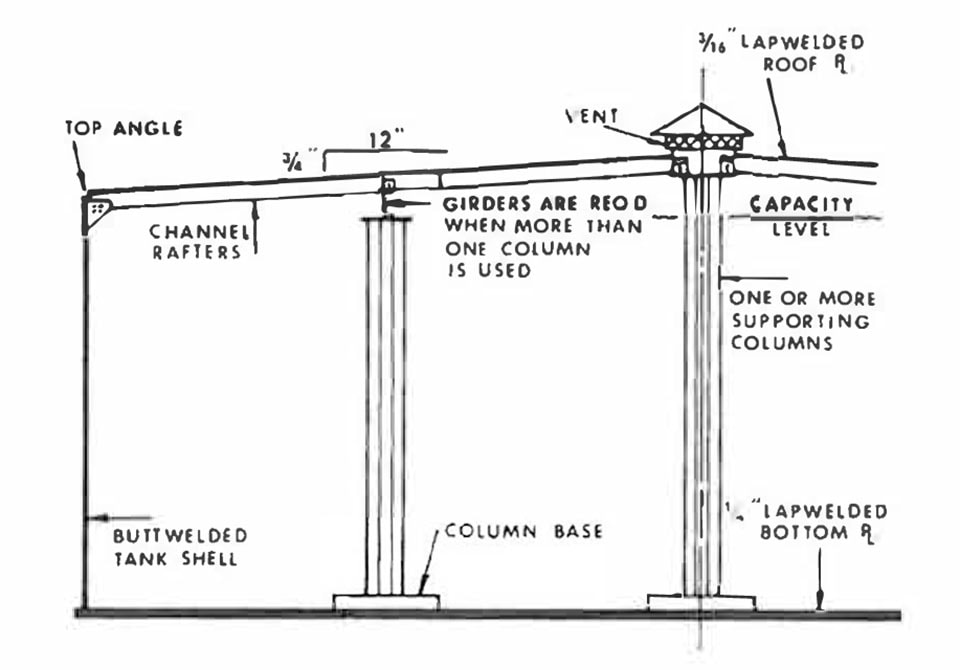

A reservoir, a tank with a diameter greater than its height, is a common type of water storage structure. It usually is built on high ground so the water will flow by gravity. Of the three types of steel water tanks, a reservoir generally is the most economical to fabricate and erect because of its low height and relative simplicity.

The roof style can be conical, toriconical, dome or ellipsoidal. Standard accessories may include shell and roof manholes, screened roof vent, inside and/or outside ladders, painter’s trolley rail, and connections for pipes as required.

Steel reservoirs weigh only about 1/8th as much as concrete ones of the same capacity. The lower weight of steel structures is especially advantageous when the construction site is difficult to reach, as the cost of moving materials to the site generally is proportional to the weight.

Typical Steel Water Storage Reservoirs

| Capacity Range of Sizes Available | Range of Sizes Available | ||||

|---|---|---|---|---|---|

| U.S. Gallons | Cubic Meters | Feet – Inches | Meters | ||

| Diameter | Height to HWL | Diameter | Height to HWL | ||

| 50,000 | 189 | 19-3 | 24-0 | 5.9 | 7.3 |

| 60,000 | 227 | 21-0 | 24-0 | 6.4 | 7.3 |

| 75,000 | 284 | 23-6 | 24-0 | 7.2 | 7.3 |

| 100,000 | 379 | 23-6 | 32-0 | 7.2 | 9.8 |

| 27-0 | 24-0 | 8.2 | 7.3 | ||

| 125,000 | 473 | 26-0 | 32-0 | 7.9 | 9.8 |

| 30-3 | 24-0 | 9.2 | 7.3 | ||

| 150,000 | 568 | 28-6 | 32·0 | 8.7 | 9.8 |

| 33-0 | 24-0 | 10.0 | 7.3 | ||

| 200,000 | 757 | 33-0 | 32-0 | 10.0 | 9.8 |

| 38-3 | 24-0 | 11.7 | 7.3 | ||

| 250,000 | 946 | 37-0 | 32-0 | 11.3 | 9.8 |

| 42-9 | 24-0 | 13.0 | 7.3 | ||

| 300,000 | 1,135 | 40-6 | 32-0 | 12.3 | 9.8 |

| 46-9 | 24-0 | 14.3 | 7.3 | ||

| 400,000 | 1,515 | 46-6 | 32-0 | 14.2 | 9.8 |

| 54-0 | 24-0 | 16.5 | 7.3 | ||

| 500,000 | 1,890 | 46-6 | 40-0 | 14.2 | 12.2 |

| 52-0 | 32-0 | 15.9 | 9.8 | ||

| 60-6 | 24-0 | 18.4 | 7.3 | ||

| 600,000 | 2,270 | 51-0 | 40-0 | 15.6 | 12.2 |

| 57-0 | 32-0 | 17.4 | 9.8 | ||

| 750,000 | 2,840 | 57-0 | 40-0 | 17.4 | 12.2 |

| 64-0 | 32-0 | 19.5 | 9.8 | ||

| 1,000,000 | 3,785 | 66-0 | 40-0 | 20.1 | 12.2 |

| 74-0 | 32-0 | 22.6 | 9.8 | ||

| 1,500,000 | 5,680 | 80-6 | 40-0 | 24.5 | 12.2 |

| 90-6 | 32-0 | 27.6 | 9.8 | ||

| 2,000,000 | 7,570 | 93-0 | 40-0 | 28.4 | 12.2 |

| 104-6 | 32-0 | 31.9 | 9.8 | ||

| 3,000,000 | 11,360 | 114-0 | 40-0 | 34.7 | 12.2 |

| 127-6 | 32-0 | 38.9 | 9.8 | ||

| 4,000,000 | 15,140 | 131-6 | 40-0 | 40.1 | 12.2 |

| 147-6 | 32-0 | 44.9 | 9.8 | ||

| 5,000,000 | 18,930 | 147-0 | 40-0 | 44.8 | 12.2 |

| 165-0 | 32-0 | 50.3 | 9.8 | ||

| 7,500,000 | 28,390 | 180-0 | 40-0 | 54.9 | 12.2 |

| 201-6 | 32-0 | 61.4 | 9.8 | ||

| 10,000,000 | 37,850 | 233-0 | 32-0 | 71.0 | 9.8 |

| 208-0 | 40-0 | 63.5 | 12.2 | ||

Standpipes

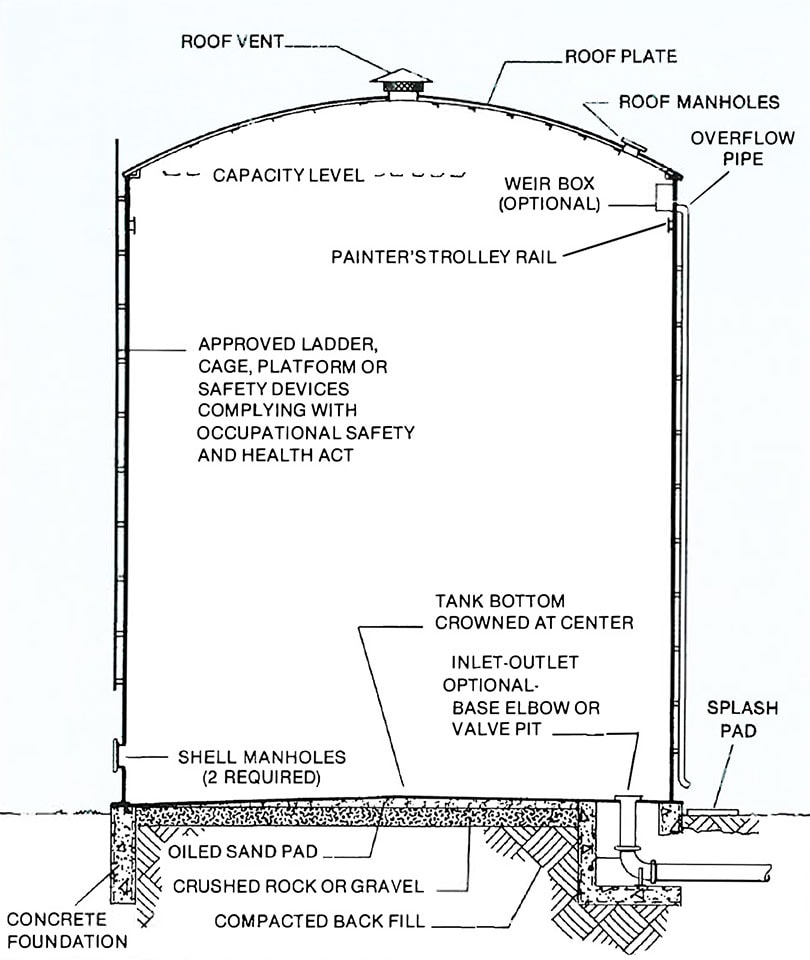

Standpipes are ground storage tanks that are taller than their diameter. They usually are built where there is little natural elevation and the extra height is needed to create pressure for water distribution.

It is important that standpipes be designed as a pleasing addition to the community skyline. Steel, because of its strength and formability, can be fabricated into many interesting and attractive shapes.

The shape of the roof may be conical, toriconical, dome or ellipsoidal, with or without ornamental trim. Standard accessories may include shell and roof manholes, a roof vent, painter’s trolley rail, fixed outside ladder, and connections or pipes as required. Inside ladders are not recommended in locations where sustained freezing weather can be expected. Safety devices for long ladders are required by law in all locations.

The standpipe’s flat bottom, like the reservoir’s is not designed to carry stress. It acts as an impervious, flexible membrane that assures reliable, “bottle-tight” construction. It usually is 1/4 inch steel plate lap welded on the top side only. These lap seams are tested for tightness using a vacuum box and a soap solution. The bottom frequently is crowned upward toward the center to accommodate a modest amount of subsoil consolidation without producing excessive tensile stressses.

Typical Steel Water Storage Standpipes

| Capacity Range of Sizes Available | Range of Sizes Available | ||||

|---|---|---|---|---|---|

| U.S. Gallons | Cubic Meters | Feet – Inches | Meters | ||

| Diameter | Height to HWL | Diameter | Height to HWL | ||

| 50,000 | 189 | 14-9 | 40-0 | 4.5 | 12.2 |

| 60,000 | 227 | 16-2 | 40-0 | 4.9 | 12.2 |

| 75,000 | 284 | 18-0 | 40-0 | 5.5 | 12.2 |

| 100,000 | 379 | 19-0 | 48-0 | 5.8 | 14.6 |

| 125,000 | 473 | 21-3 | 48-0 | 6.5 | 14.6 |

| 150,000 | 568 | 23-3 | 48-0 | 7.1 | 14.6 |

| 200,000 | 757 | 24-10 | 56-0 | 7.6 | 17.1 |

| 250,000 | 946 | 27-9 | 56-0 | 8.5 | 17.1 |

| 300,000 | 1,135 | 28-5 | 64-0 | 8.7 | 19.5 |

| 400,000 | 1,515 | 32-10 | 64-0 | 10.0 | 19.5 |

| 500,000 | 1,890 | 34-7 | 72-0 | 10.5 | 21.9 |

| 600,000 | 2,270 | 37-10 | 72-0 | 11.5 | 21.9 |

| 750,000 | 2,840 | 42-6 | 72-0 | 12.9 | 21.9 |

| 1,000,000 | 3,785 | 46-4 | 80-0 | 14.1 | 24.4 |

| 1,500,000 | 5,680 | 56-9 | 80-0 | 17.3 | 24.4 |

| 2,000,000 | 7,570 | 65-6 | 80-0 | 20.0 | 24.4 |

| 2.500,000 | 9,465 | 69-10 | 88-0 | 21.3 | 26.8 |

| 3,000,000 | 11,360 | 76-6 | 88-0 | 23.3 | 26.8 |

| 4,000,000 | 15,140 | 84-6 | 96-0 | 25.8 | 29.3 |

| 5,000,000 | 18,930 | 94-6 | 96-0 | 28.8 | 29.3 |

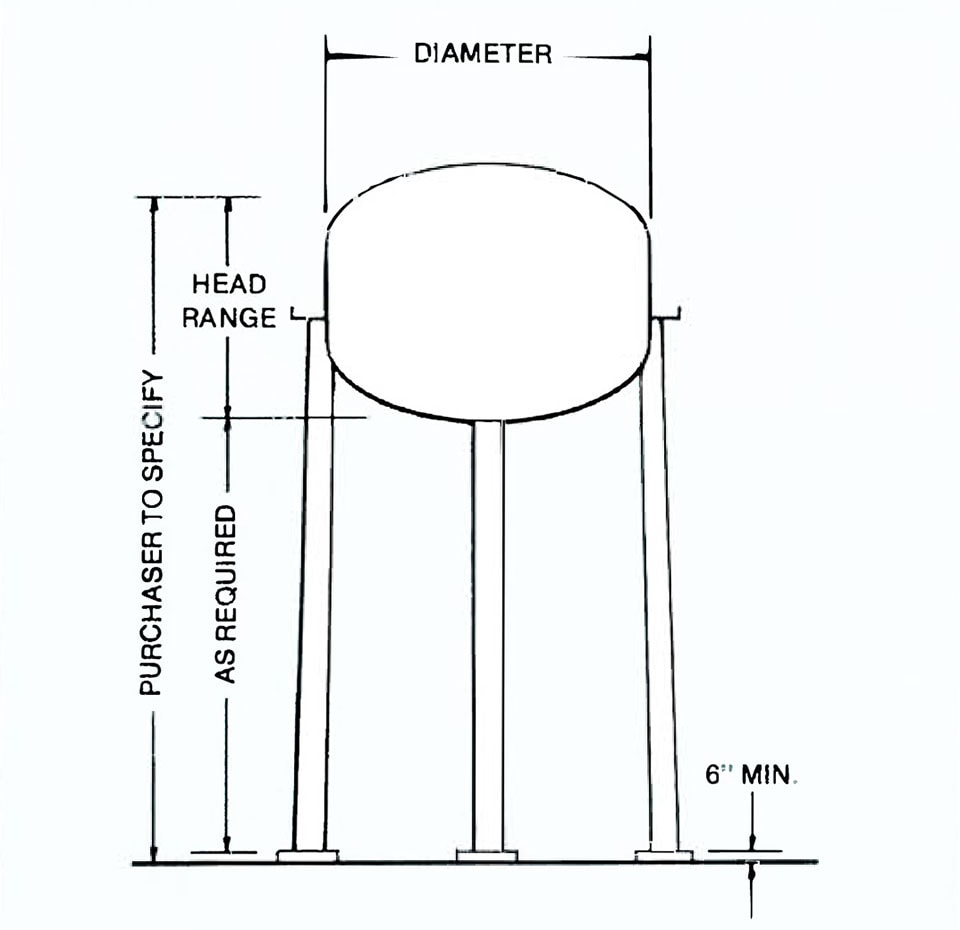

Elevated Tanks

Elevated steel water tanks have two primary components-the tank itself and its supporting structure. They ordinarily are used where natural ground elevation is not sufficient to assure distribution of water by gravity at suitable pressure.

Because of their height and supporting structure, elevated tanks offer virtually unlimited possibilities for attractive design. Steel’s strength and versatility make it the natural material for construction of safe, economical and eye-catching structures.

Elevated tanks can be categorized into several different types. The various diameters and head ranges for those shown in the accompanying diagrams and tables are only representative, and may vary with individual fabricators. Specific diameter/head range combinations should be decided by the tank fabricator within the limits indicated in the tables. Height should be specified by the purchaser as the dimension between the top of the foundation and the overflow level of the tank. Further dimensions, which are a function of the fabricator’s standard, should not be specified.

The double ellipsoidal tank has a cylindrical side wall, an ellipsoidal bottom and roof, and a top capacity level in the roof several feet above the top of the cylindrical shell.

Typical Double Ellipsoidal Steel Elevated Tanks

| Capacity | Range of Sizes Available | ||||

|---|---|---|---|---|---|

| U.S. Gallons | Cubic Meters | Feet | Meters | ||

| Diameter | Head Range | Diameter | Head Range | ||

| 25,000 | 95 | 18-20 | 12.5-15.5 | 5.5-6.1 | 3.8-4.7 |

| 30,000 | 114 | 18-20 | 15.0-16.5 | 5.5-6.1 | 4.6-5.0 |

| 40,000 | 150 | 22-23 | 15.0-17.0 | 6.7-7.0 | 4.6-5.2 |

| 50,000 | 189 | 22-24 | 18.0-20.0 | 6.7-7.3 | 5.5-6.1 |

| 60,000 | 227 | 22-25 | 19.0-23.0 | 6.7-7.6 | 5.8-7.0 |

| 75,000 | 284 | 26-30 | 16.0-24.0 | 7.9-9.1 | 4.9-7.3 |

| 100,000 | 379 | 28-30 | 20.0-25.0 | 8.5-9.1 | 6.1-7.6 |

| 125,000 | 473 | 30-32 | 23.0-28.0 | 9.1-9.7 | 7.0-8.5 |

| 150,000 | 568 | 32-34 | 24.5-29.5 | 9.7-10.4 | 7.5-9.0 |

| 200,000 | 757 | 36-38 | 28.0-29.5 | 11.0-11.6 | 8.5-9.0 |

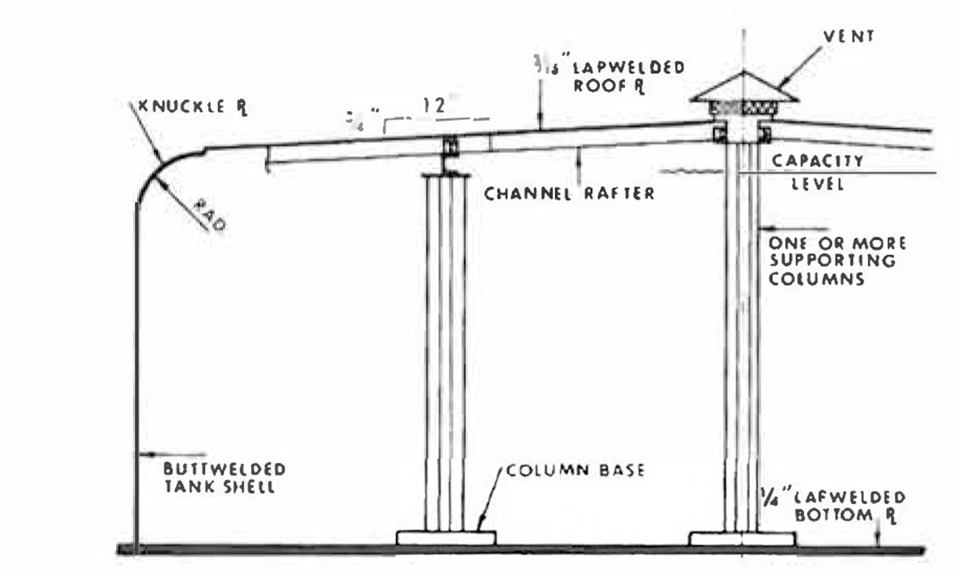

Column and Rafter Supported Cone Roofs

Column and Rafter Supported Roof with Knuckle

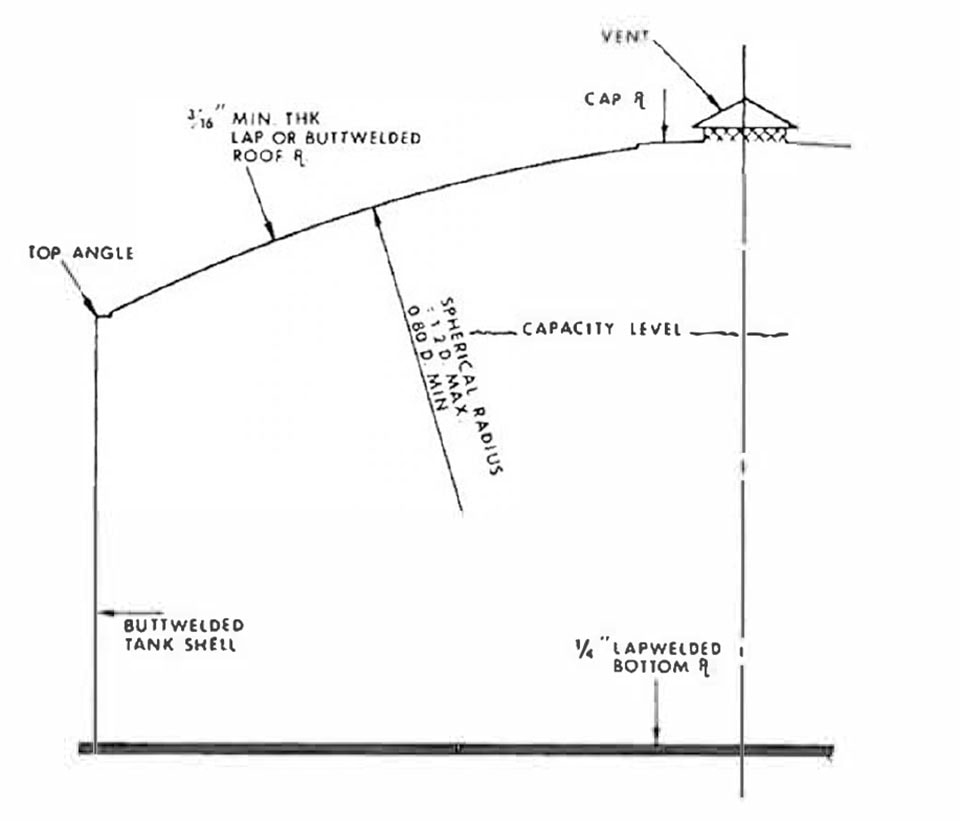

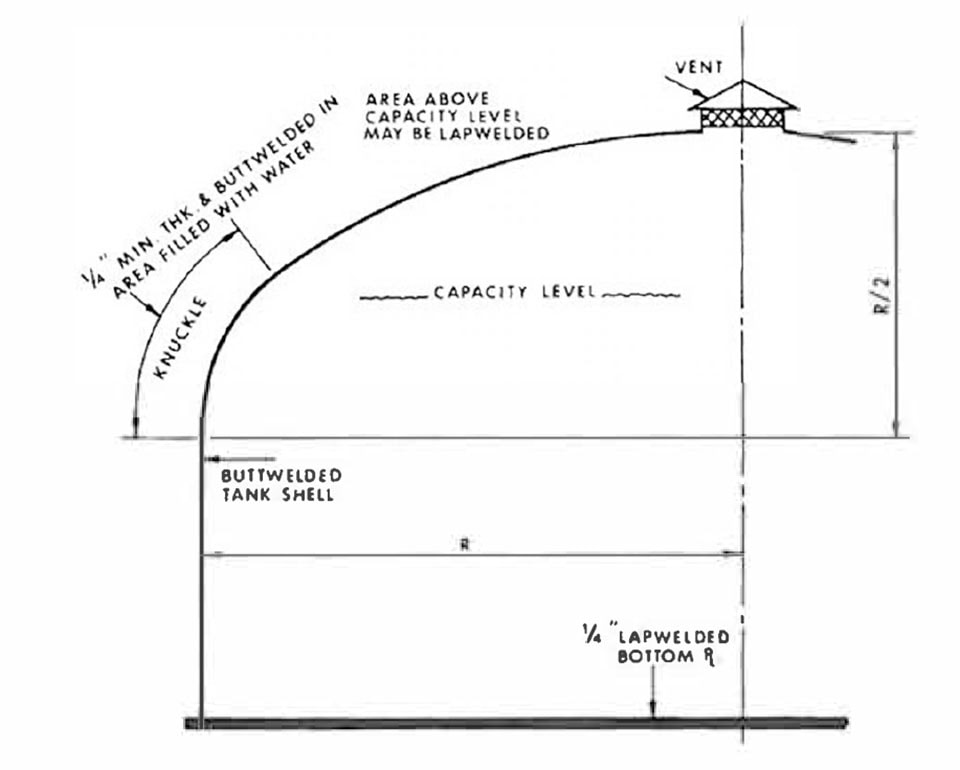

Self-Supporting Dome Roof (or Umbrella Roof)

Self-Supporting Ellipsoidal Roof

Special Applications

Aesthetics

Unique Operations

Steel water tanks may be designed to accommodate special operational requirements. One example of this is the dual purpose tank that provides more than one storage compartment. A typical configuration includes a lower storage compartment, very similar to a pipe, which also supports an elevated tank. Each functions as a separate water storage vessel. Where applicable, the dual purpose tank offers potential savings in both property and maintenance costs by combining two tanks into one structure.

The flexibility of steel tanks also allows for alternate applications that address community concerns or local building standards. One such example would be a buried, or partially buried, steel tank. If a low profile tank is needed and the demand for water storage exceeds the available site conditions, steel tanks can be – and have been – successfully buried.

Today’s tank coatings and the integrity of steel will provide countless years of low cost water storage. In contrast to other materials, steel tanks built to the AWWA D100 standard will also provide assurance that your tank will be leak-free.

For more information about special application tanks, contact a STI/SPFA member tank company.

More Information

Resource Type

- Guidance

Topic

- Field Erected Tanks