Global disruption and geopolitical risk created by phenomena like the pandemic and the Russian invasion of Ukraine resulted in unreliable global supply chains and shortages of essential goods. This type of unpredictable disruption highlights the urgency to invest in reshoring essential product ecosystems. Overcoming the manufacturing workforce skills-gap is critical to this effort.

Unfilled jobs were the primary reason that 70 percent of companies fell behind in scheduled production, leading many industrial leaders to identify labor shortages as a challenge to growth. The skills gap must be resolved in order to reshore supply chains that are crucial to U.S. national and economic security.

The reshoring trend and the metrics of TCO

Much of the strength of the reshoring trend has been due to more companies becoming familiar with a broad range of factors (costs and risks) they had previously ignored. A broad range of costs and risks can be quantified using the Reshoring Initiative’s online Total Cost of Ownership Estimator®.

The Impact of Using TCO shows that shifting decisions from a price basis to TCO can be expected to drive reshoring of 20% to 30% of what is now imported. The percentage would be higher in heavy fabrications and tanks where the freight cost is relatively high vs. the labor savings offshore.

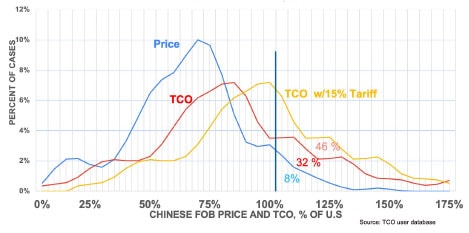

About 60% of companies make import decisions based on price instead of TCO. In Figure 1, the percentage of the cases that the U.S. wins increases from 8% based on price, to 32% based on TCO, to 46% if a 15% tariff applies.

Chinese Price and TCO, % of U.S.

Figure 1: Chinese price & TCO as a percentage of U.S. price & TCO

Source: TCO User Database Reshoring Initiative

Building a comprehensive labor pool

It is fundamental that we engage a broader labor pool by: increasing diversity, equity, and inclusion (DEI); adding flexibility models to attract and retain talent; overcoming misperceptions of manufacturing careers; re-skilling and up-skilling existing workers; and adopting public-private partnerships to provide training that aligns with the needs of industry. Simply put, we must train a larger and more diverse skilled workforce.

DEI and flexible workplace benefits

Women in manufacturing are a prime DEI example. Although women make up 47% of the total workforce, and earn more than half of the associate, undergraduate and graduate degrees awarded in the U.S., they make up only about 30% of the people employed in manufacturing industries. Manufacturers should tap into this highly educated labor pool.

Implementing flexible work models such as flextime or hybrid work will expand and diversify the talent pipeline and result in higher employee engagement and increased productivity.

Manufacturing misperceptions – recruitment is key

Overcoming two common manufacturing misperceptions is key to recruitment. First training vs. degrees: Multiple government websites show income as a function of the number of degrees, while failing to mention that an apprentice graduate has an income similar to a 4-year university graduate. I convinced the Labor Department to change one page but there are many more online. This data is the basis for the unrelenting societal pressure to go to university. See an example Education pays, 2021: Career Outlook: U.S. Bureau of Labor Statistics (bls.gov).

Second, change the misperception that manufacturing careers are dark, dirty, dangerous, dead-end and declining – the “5Ds”. To overcome these misperceptions, the industry needs to demonstrate that modern manufacturing is a high-skilled, high-tech, high-paying, stable, safe career choice. By promoting the success of reshoring, we overcome the “declining” issue.

Re-skilling and up-skilling

Many manufacturing jobs now require higher-tech skills to support advanced manufacturing, automation, robotics, and the Internet of Things (IoT); all of which increase productivity, drive innovation and boost U.S. competitiveness.

New methods of training like Industry 4.0 are improving instruction and safety conditions through remote experts, 3D work instructions, augmented reality, real time monitoring and more.

For example, aerospace giant, Lockheed Martin, has embraced MR (mixed reality) headsets for training, manufacturing, and assembly, boosting productivity while saving time and money.

Training initiatives

Today, just 0.5% of global GDP is invested in lifelong learning but broad investment in re-skilling and up-skilling will likely boost the global GDP by $6.5 trillion by 2030. Here are some initiatives that are collaborating to close the U.S. manufacturing skills gap.

The National Tooling and Machining Association (NTMA) is recognized by the Department of Labor as an Apprenticeship Ambassador, focusing on filling the skills gap through access to training and educational resources that are industry-backed, industry-tested, and industry-proven.

In 2022, 12 Midwest institutions partnered to form a semiconductor-focused network. The collective, named the Midwest Regional Network to Address National Needs in Semiconductor and Microelectronics will develop innovations in higher education to prepare the workforce to support the reshoring of the semiconductor and microelectronics industry.

The Center for Manufacturing Advancement (CMA) is a VA state-funded project at the Institute for Advanced Learning and Research (IALR). “There has never really been a program designed like this to take someone that walks off the streets that may have never been exposed to welding or machinery or anything and then in four months be able to walk in and get an attractive job with a salary that supports themselves and their families,” said President of IALR, Telly Tucker.

Reshoring success

Let’s collaborate to support skilled workforce development and reshore supply chains that are essential to U.S. national and economic security. For help or to help, contact me at 847-867-1144 or harry.moser@reshorenow.org.