50,000 Gallon Double Wall ACT-100 Leachate Tank

50,000 Gallon Double Wall ACT-100 Leachate Tank

Appleton, WI, United States

This 50,000 gallon double wall ACT-100 tank weighs over 70,000 lbs. and includes three 13’ high manway risers for tank access and leachate loadout. The tank is interior blasted to SPCC-SP10 and coated with two coats of Tnemec #61 epoxy lining for added chemical resistance. The inner tank shell is constructed of 3/8” steel to accommodate a 12’ foot burial depth. This 50,000 gallon ACT-100 tank provides leachate storage to be transported from the landfill to a wastewater treatment facility in Green Bay, WI.

Twin Double Wall Cryogenic Tanks at New Ethane Import Terminal in Coatzacoalcos Veracruz

Twin Double Wall Cryogenic Tanks at New Ethane Import Terminal in Coatzacoalcos Veracruz

Coatzacoalcos, Veracruz, Mexico

Contractor was responsible for the engineering, procurement, fabrication and construction of two double-walled cryogenic tanks in Mexico. These identical double-walled tanks are approx. 150’ diameter x 127’ high, dome roof with suspended insulated deck. Having over 6,500,000 lbs (3,250 tons) of steel, most of the inner and outer tank components consisted of 9% Nickel steel plate. The terminal’s location encounters significant rainfall and wind events throughout the year. The contractor was able to accelerate the construction schedule by several months to meet the owners needs.

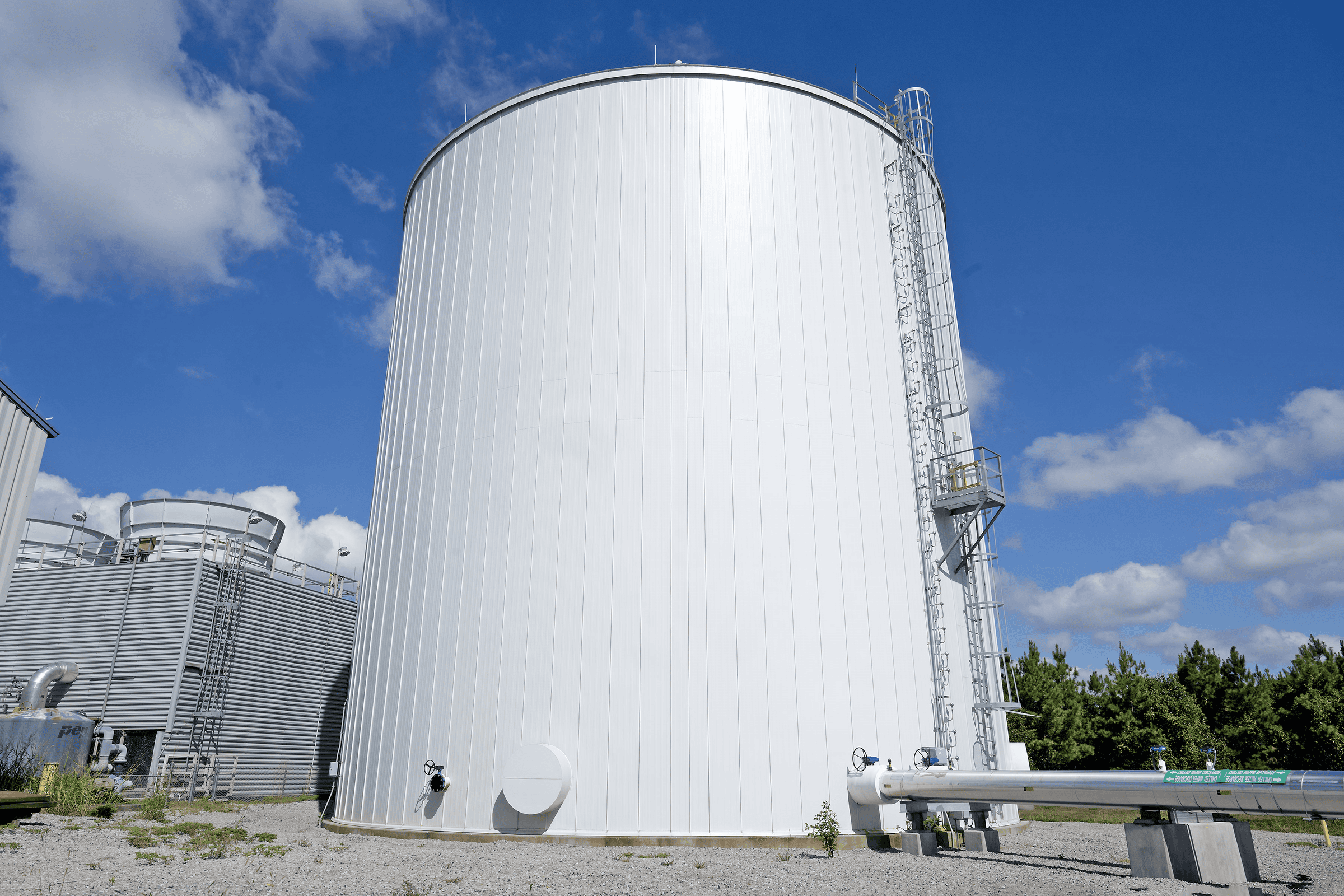

Thermal Energy Storage Tank

Thermal Energy Storage Tank

Huntsville, Alabama, United States

The project consisted of the engineering, foundation design, procurement, fabrication and construction of a 60ft diameter x 60ft high “All Steel” Thermal Energy Storage (TES) tank that will provide significant operational savings reducing cooling costs for the client.

Winner

(4) 26.8m (87′-9) X 20 barg (290psig) LPG Spheres

(4) 26.8m (87′-9) X 20 barg (290psig) LPG Spheres

Haina, San Cristobal, Dominican Republic

This project consisted of the engineering, procurement, fabrication, construction, full field post weld heat treating, and painting of (4) 26.8m (87′-9) x 20 barg (290psig) LPG spheres for Refidomsa at the Terminal Haina in San Cristobal, Dominican Republic.

3.5MG Triple Use Water Tank

3.5MG Triple Use Water Tank

Foothills Area, NC, United States

The 3.5 M gallon tank was designed for triple use (fire/process/cooling circulation tank). It was erected on an very busy, very secure project site with over 2,000 workers, heavy equipment, limited access and constant OSHA and third-party safety oversight. The project site is in the foothills of North Carolina and the tank site had an 80′ drop-off on one side, within 25′ of the tank.

Northwest Pump Station

Northwest Pump Station

Abilene, Texas, United States

This project consisted of 12″ through 36″ steel pipe with a wall thickness of 1/4″ and 3/8″. Working pressure ranged from 50psi on the suction side of the pumps to 200psi on the discharge side. This project was partially buried with cement mortar coating and exposed with epoxy coating. Pipe connection types were flanged, bell & spigot, flexible coupling, and buttstraped. Flanges used were AWWA C207 ring ‘D’, ‘E’, ANSI B16.47A and ANSI B16.5. All pipe was lined with epoxy meeting NSF61 standards.

- « Anterior

- 1

- …

- 4

- 5

- 6

- 7

- 8

- …

- 22

- Siguiente »