This post is also available in:

English (Inglés)

In the American steel tank and pipe fabrication industry, where precision, safety, and innovation are non-negotiable, the challenge of workforce development has become increasingly urgent. A generation of skilled workers is approaching retirement and younger generations overlook skilled trades, trade schools are under-enrolled, and automation is rapidly reshaping the shop floor. Recent years have also indicated challenges within operational parameters; ranging from delaying critical infrastructure projects, supply chains, inflation and now tariffs within this industry. As a result, fabricators and suppliers are facing a sobering question: how can we build a resilient workforce that can adapt and thrive in this evolving industrial landscape?

The Manufacturing Institute indicates that 3.8 million manufacturing jobs could sit unfilled by 2033, costing the economy $1 trillion in lost output. This article examines the current talent crisis and highlights how industry leaders are deploying workforce development strategies; spanning from apprenticeship programs to seasoned veteran outreach to secure their talent pipelines. We also explore how automation, industry collaboration, and realigned training curricula are reshaping the human capital equation in steel tank fabrication.

The Workforce Crisis: Understanding the Challenge

The steel tank sector, a key subset of the broader steel fabrication industry, supports essential infrastructure in fuel storage, water systems, and industrial processing. However, despite its significance, the sector is battling a mounting skills gap:

- An aging workforce: According to the U.S. Bureau of Labor Statistics, more than 25% of skilled tradespeople are aged 55 or older.

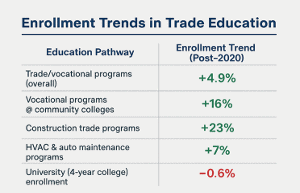

- Shrinking vocational interest: High school graduates increasingly favour white-collar careers over blue-collar trades.

- Technological disruption: From automated welding to CNC plasma cutting, the modern tank fabrication shop demands hybrid skill sets that blend craftsmanship with tech fluency.

The Crisis by the Numbers:

In an article by James Manning, it is highlighted that 460,000+ manufacturing jobs remained vacant in early 2025 i.e. with welders, CNC machinists, and maintenance technicians hardest to find and there is a 5:1 retirement-to-new-hire ratio plague welding roles as vocational enrollment lags. Furthermore, data from the Steel Tank Institute/ Steel Plate Fabricators Association (STI/ SPFA) shows that 90% of manufactures could hire new employees today if the workforce was available.

Unlike general manufacturing, steel tank and pipe fabrication also face unique pressures such as it demands;

- Mastery of specialized processes (e.g., AWWA D102 coating systems, ASME pressure vessel standards)

- Strict safety or compliance expertise for critical applications (potable water, fuel storage)

- Adaptation to “Industry 4.0” tools like robotic welders, AI-driven inspection drones, and BIM software.

Building Sustainable Talent Pipelines: Real-World Strategies

To future-proof their operations, forward-thinking manufacturers are investing in workforce development strategies rooted in practicality and long-term vision.

Apprenticeship and In-House Training

Apprenticeship pathways, often certified in partnership with local technical colleges, allow employers to shape workers according to industry needs while offering clear career trajectories.

These programs typically focus on:

- Welding certifications (GMAW, FCAW, TIG)

- Computer-Aided Design (CAD) interpretation

- Tank compliance standards (UL 142, API 650)

An apprenticeship model not only builds skill but also fosters loyalty and reduces attrition.

Growing Talent from Within: A Fabricator’s Perspective

Jay Forni Jr., President of Jifco, Inc., shared his perspective on tackling the skills gap in steel fabrication, highlighting key strategies for effective workforce development;

“Our required skills are unique to us. Very few people have applied for a job at our top tier skill levels. Many of our project managers and mid-level management started out pushing a broom. We hire entry level employees and provide training for whatever skill path(s) they choose. Each step of the process that is completed earns the employee a pay raise.”

On the external hiring front, Forni adds,;

“Finding people with the skill sets required. This applies to blue collar and white collar projects. Five to ten years ago, it was difficult to hire anyone because of the perceived bias against blue collar employment. In the last few years, many people have decided to look at manufacturing jobs like ours because the benefits and salaries are available at a more rapid pace.”

Steve Ladd, President & CEO of Steel-Pro Incorporated contributed the following;

“Automation plays a big role in enhancing our manufacturing processes, but it doesn’t replace skilled welders; it complements them. The ability to complete tasks more efficiently with advanced equipment helps us attract and retain talent,” says Mr.Ladd. “What truly sets us apart is our employee ownership culture. We openly share financials, promote from within, and provide clear pathways for growth, from welding and fabrication to quality control and leadership roles.”

“Our biggest challenge is the limited labour pool, especially in our region of Maine where few companies do what we do. That’s why we focus heavily on recruiting through trade schools and even start engaging students as early as grade school to showcase welding as a rewarding career.” He concluded.

Partnerships with Trade Schools and Community Colleges

Companies are proactively engaging with technical institutions to co-create curriculum aligned with modern fabrication needs. For instance, the American Welding Society (AWS) has collaborated with schools to develop industry-specific modules in welding and NDT (non-destructive testing) and offering scholarship programs.

Benefits include:

-

Early access to emerging talent

- Exposure for students to real-world challenges

- Fast-tracked certification and onboarding

In this regard, The STI/SPFA Scholarship, managed through the American Welding Society (AWS) Foundation offers futuristic programs targets students pursuing welding careers, particularly in steel tank and pipe fabrication, awarding financial support while advocating for a fundamental shift in how society/ prospective young students perceives skilled trades as lifelong learning.

By emphasizing how lucrative a career this can be, where welders earn competitive salaries and work with cutting-edge technologies, the initiative dismantles legacy stereotypes and positions manufacturing as a high-impact, innovation-driven field.

By integrating industry exposure into early or during the degree stage of education, fabricators can reignite interest in blue-collar careers among the next generation.

Upskilling the Existing Workforce

A study by the Manufacturing Institute found that employees trained on the job are 52% more likely to stay for over three years. It is proven to be faster, cheaper as well as a more effective tactic. The advent of Industry 4.0 technologies has made upskilling a non-negotiable priority. CNC machine operation, robotic welding, and digital fabrication tools require existing staff to evolve from manual technicians to tech-savvy operators.

Employers are responding with:

- Micro-credential courses

- Vendor-led software training

- Cross-functional skill development i.e. machining quality control and quality assurance, and robotic programming, can be a clear and more agile way forward.

For example, retraining a manual welder to operate a robotic arm doesn’t just fill a skill gap, it adds value across the production line.

Veteran and Second Chance Hiring Programs

Steel fabrication companies are increasingly turning to non-traditional talent pools, including military veterans and individuals re-entering the workforce post-incarceration. Veterans often bring discipline, mechanical skills, and leadership experience, all transferable to fabrication environments.

Organizations like Hire Heroes USA and Work Opportunity Tax Credit (WOTC) support such initiatives, offering both workforce development and fiscal incentives.

Mentorship and Succession Planning

An often-overlooked component of workforce strategy is intergenerational knowledge transfer. As older workers retire, their expertise risks being lost unless captured and passed on. Companies are implementing mentorship schemes that pair senior welders or plant supervisors with junior employees to accelerate onboarding and institutional memory retention.

The Industry Landscape: Evolving Roles and Future Skill Sets

A McKinsey study shows that companies incorporating technology and workforce training simultaneously see productivity gains 30% higher than those who adopt automation or agile frameworks without workforce development plans.

The skills needed in the steel tank and pipe sector are no longer limited to physical fabrication. Digital fluency, data interpretation, and safety compliance are now fundamental job functions.

Key emerging roles include:

- Automation Technician: Operates and maintains robotic fabrication arms.

- Quality Control Analyst: Applies statistical tools and software for precision compliance.

- Industrial Safety Specialist: Ensures tanks meet environmental and structural codes.

The following table demonstrates the skill shifts in steel fabrication industry;

| Traditional Role | Emerging Hybrid Role | Required Add-On Skills |

| Welder | Robotic Weld Technician | Programming, machine vision basics |

| Quality Inspector | Digital NDE Analyst | Drone operation, AI diagnostics |

| Project Manager | BIM Integration Specialist | 3D modeling software, IoT sensors |

Augmented Reality (AR) tools like Microsoft HoloLens are being used to project repair instructions in real time, while ergonomic exoskeletons help reduce strain during physically demanding tasks like overhead welding. Additionally, soft skills like communication, teamwork, and adaptability have become just as vital as technical prowess in increasingly collaborative and tech-integrated workshops.

Collaboration and Resource Networks

Strategic partnerships are crucial to bridging the workforce gap. The following organizations are at the forefront:

Steel Tank Institute/Steel Plate Fabricators Association (STI/SPFA)

A central voice for the steel tank, pipe and pressure vessel community, STI/SPFA provides:

- Scholarship program for welders

- Technical training information

- Safety and compliance resources

- An advocacy program focused on important legislative issues affecting the steel fabrication industry

“STI/SPFA continues to add programs and resources to help member companies grow the workforce in the steel fabrication industry, including an advocacy program that has seen tremendous growth,” commented Tim O’Toole, STI/SPFA Executive Vice President.

“Our organization works closely with key departments and members of Congress, advocating for legislation that makes a positive impact on the industry.”

American Welding Society (AWS) Scholarships

AWS sets global standards in welding education and certification. Through its SENSE program and scholarship networks, AWS nurtures young welders and promotes diversity in the trade.

The STI/SPFA Scholarship, managed through the American Welding Society (AWS) Foundation, exists at the forefront of cultivating tomorrow’s workforce.

The AWS Foundation further amplifies this mission, awarding more than $2.5 million in scholarships, redefining career readiness for a future where technical prowess, sustainability, and advanced digital fluency converge.

Workforce Development Boards

At the regional level, WDBs connect employers with government-sponsored training funds, job seekers, and vocational guidance. Many boards also facilitate Registered Apprenticeship Programs (RAPs), offering a pathway for companies to grow talent organically.

Veterans Employment Toolkit

A U.S. Department of Labor resource, this toolkit helps businesses tap into military-experienced talent pools and understand the process of onboarding veterans, including recognition of military certifications in civilian terms.

In a nutshell, showcasing cutting-edge tech, like VR welding demos to engage young minds. Embedding deeper into education through curriculum co-design and material donations can build early talent pipelines. At the policy level, supporting tax incentives for apprenticeships and advocating for skilled immigration will unlock access to a broader, future-ready workforce.

From Paychecks to Purpose: The New Blueprint for Attracting and Retaining Talent

It is time for the industry to reframe the narrative as well. The most forward-thinking steel fabricators are realizing that retaining existing talent requires more than just competitive wages, it demands a cultural shift. They’re fostering purpose-driven, human-first workplaces where employees feel pride in their indulgence. For example, some companies have introduced “Legacy Project” badges, tagging employees’ names on tanks they’ve helped build, creating a lasting sense of ownership.

Reinforcing a mission-focused team spirit, fabricators should deploy dedicated crews to support emergency municipal repairs, such as during the water crises. Instead of traditional career ladders, companies need to introduce more dynamic career lattices, offering both technical and leadership development tracks in order to enhance integration of advanced technology and the worker experience. Programs like “Skill Wallets” give workers portable, recognized credentials such as AWS or API certifications, empowering them to take ownership of their career progression.

Embracing the Ethos; Fabricating the Future

The steel tank and piper fabrication industry’s future hinges on bold innovations and agility especially when it comes to talent. Whether it’s through structured apprenticeships, strategic partnerships, or automation-readiness training, companies that invest in workforce development today are positioning themselves as leaders tomorrow.

This isn’t just about filling roles. It’s about reimagining who builds our infrastructure, how they learn, and why it matters. By embracing both people and progress, the steel tank and pipe sector can weld together a workforce built to last.